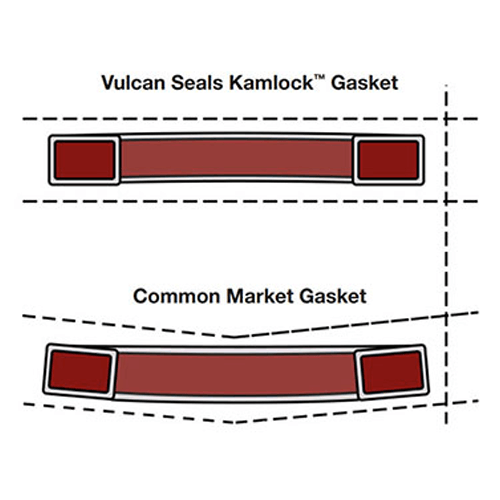

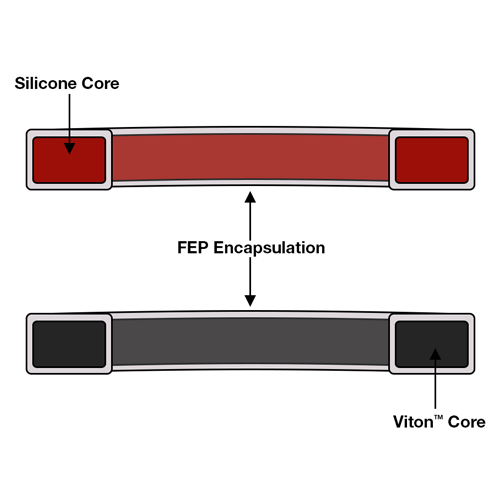

Superior Gasket Quality

Vulcan Seals gaskets are produced to be the highest quality available in the market. We have eliminated common product issues found in the market, guaranteeing a consistent fit and reliable performance.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.